How to make a USB PD charger -Consider how to balance miniaturization and high reliability

Assignments for carrying mobile devices, power adapters

For mobile devices, power adapters have long been an important issue.Due to the size of the power adapter, the efficiency level, and the lack of power output, the miniaturization of the supported devices is impaired, and the portability is impaired.

The current USB Power Delivery (USB PD) can supply up to 100W power in parallel with data transmission with one cable.With this convenience, USB PD is becoming a charging method that is preferred by small and medium -sized equipment.However, the challenge in introducing USB PD is to supply a variety of output voltage at a higher power level for quick charging, which is inefficient, inefficient, expensive, and large.It can be said that it is to do.

The use of a wide band gap semiconductor such as GAN power devices is one of the approaches to improve adapter efficiency and miniaturization, but this semiconductor is a new technology in the field, and it is a current means.It is expensive.As a replacement, you can take advantage of the advances in topology such as active clamp fragments, and use the standard Super Junction Mosfet to promote the design of the adapter while relying on the proven technology.

We live in a world where mobile devices continue to increase, carry multiple devices such as smartphones, laptops, tablets, and carry many wearable equipment for utilities such as health monitoring.Manufacturers have been investing a large amount of funds in R & D to meet consumers' demands, such as improving functions, miniaturization, and portability.

What I realize on a trip is that the miniaturization of the device itself has made a major progress, but the necessary power adapters and chargers are slightly delayed, and may be more bulky than the equipment.In particular, this is when traveling to areas where multiple chargers are needed to match the voltage conditions and connector requirements of several devices.

Obviously, it takes some standardization to reduce charging and reduce the number of chargers that must be carried, and at the same time, to reduce electronic device waste, which occurs every year.

Charging world that changes with USB PD

USB 1.1 in 2.5 W (5V, 500mA) power supply is required, USB 3.In 0, the supply power is 4.It is increased to 5W (5V, 900mA), but this power supply capacity is only compatible with small devices such as smartphones.The USB PD specifications released by the USB Promoter Group in 2012 can transmit up to 100W power, which allows power supply to larger devices, such as laptops and motors, and quickly charging mobile devices.The versatility is also improved by the variable function of the output voltage.This standard has many advanced functions, such as two -way power supply (power supply can be made from either end of the cable) and high -speed roll swaps that allow data to transmit data and power at the same time with the same cable.

When the USB PD was first released, a voltage and current that could supply power was defined based on six power profiles.But USB PD 2.In 0, the power supply was 0 because this profile was eliminated and the method with higher flexibility was tolerated..You can now respond to any request from 5W to 100W.

The flexibility of such USB PD may reduce the number of necessary chargers, while individual chargers are not necessarily smaller, and that point is a design task.increase.Power adapters not only need to comply with USB PD standards, but also need to improve their power density at reasonable costs.

The method of realizing this has been fully established, and it is intuitively known that improving efficiency is extremely important for improving power density from the point of electricity technology.The more efficient design is, the less exhaust heat, so you can achieve the required power consumption in a narrower surface area.In order to improve efficiency, high -efficiency circuit configuration, parts improvement, especially key switching elements.If the dynamic loss of this switching element is low, the switching frequency can be increased, so that bulky parts such as magnetic elements can be reduced.

Is the adoption of GAN optimal?

At present, one of the most notable areas is a wide band gap device such as gallium nitride (GAN) FET, which has many benefits from the viewpoint of low loss, high temperature operation, and high -speed switching frequency.But these devices are still relatively new and quite expensive.In addition, long -term use is somewhat inadequate, so if the same results can be obtained, the silicon -based technology, which has a track record and sufficiently tested, is preferred.

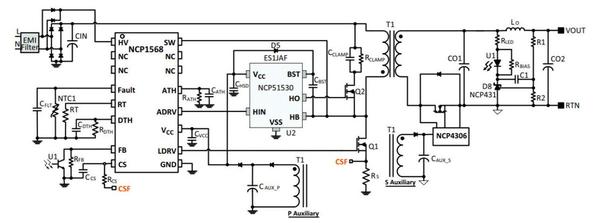

One of the topology, which has attracted attention as a solution to the latest power adapter needs, is the active clamp fleback (ACF).Since this is the use of variable frequency, it is possible to switch (ZVS) of Super Junction (SJ) FET over a variety of loads and line conditions.This topology has been introduced by the on-semiconductor AC-DC ACF pulse width modulation (PWM) IC "NCP1568".By combining this with the 700V-2A half bridge driver "NCP51530", you can realize a platform based on future power adapter design.

The NCP1568 functions as a controller and provides intelligence to the power supply system, enabling high -density and high -efficiency power design.Along with the ACF, the controller operates in discontinuous conduction mode (DCM), and the power consumption when standing is 30MW and the efficiency of light load is improved.As a result, it is possible to comply with the latest efficiency specifications such as EU COC Tier 2.This design is optimized for introducing USB PD while minimizing the required external circuits.

Since it operates at 100kHz to 1MHz, it has the advantage of miniaturizing magnetic elements, which can double the power density compared to the conventional flyback design.This solution is 93 by using SJ FET.It can achieve 5%peak efficiency and operates up to 400kHz.The NCP1568 can also increase the switching frequency and further improve the power density by using it in combination with Egan FET.

While the NCP1568 provides intelligence and control, the NCP51530 is a high -side low -side integration driver, and two N -channel power MOSFET provides high -efficiency power switching at a maximum of 700V voltage level, and even in narrow spaces.You can achieve high -performance power solutions.The NCP51530 is ideal for high frequency movements because the propagation delay time is short and the rise and descent time is high speed.The strict matching of propagation delays (5NS) can achieve efficiency improvement for all purposes.

After all, is GAN good?Is it okay to use silicon?

The USB PD specification is extremely effective in eliminating the issues that have become the root of various adapters for the huge number of mobile devices used today.With this rationalization, the designers can focus on smaller efficiency and efficiency of these adapters again, and is wasted many improvement measures that have been introduced for the purpose of improving portability of portable equipment to constrain the adapter size.You can not do it.

While wanting to move to a wide band gap technology such as GAN to deal with the task of power density, GAN is relatively new and has no sufficient track record, so many people are extremely reliable.However, we believe that the introduction of GAN is risky.

By combining high -efficiency topology (ACF) such as this time and high -frequency movement that can reduce parts size, we can meet the current market needs.These advantages can be drawn out with a highly reliable and proven silicon -based Super Junction FET.In addition, these solutions are compatible if the GAN device is mature.

With the combination of high -performance and proven technology, the issues of the power adapter are solved.